F Series of CNC Flatbed Vinyl Cutter

An efficient solution of perforation cutting, half cutting, creasing, marking, etc. With more output and less cost of labor

the cutter is designed for contour cutting of graphics without a cutting die.

The cutter is ideal for road &traffic safety signs, automotive aftermarket, signage and more.

|  |  |

| Custom Decals | Reflective Signs | Reflective Signs |

| Auto Feeding SystemConveyor is able to accomplish long seamless cutting / plotting. |

| Fast Registration Marks Detection with CCD CameraWith Gunner’s software, it is able to generate contours in one-click, and it is easy to add registration marks.CCD camera, used in combination with related software is applied to detect the intricate dieless contours fast and more efficiently. Problems caused by position error of human, poor quality printing are resolved using the CCD camera. CCD camera is applied for wide varieties of medias. |

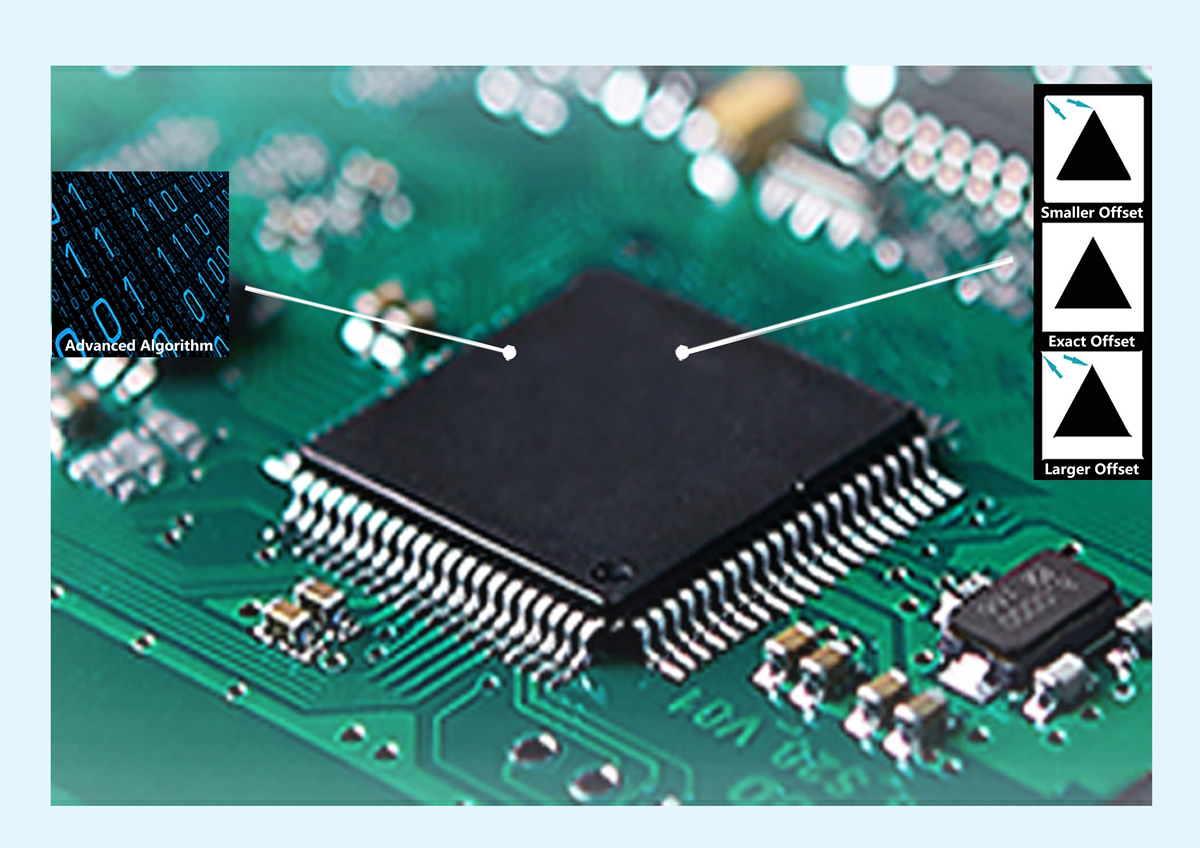

| Making Blade-tip Compensation by HardwareOur system makes blade-tip compensation by hardware(main board) instead of software, the cutter works with constant high precision no matter what kind of CAD / CAM software is applied. |

| One-click to Clear HistoryOne-click deletion button for the currently print document and clear it completely from buffer memory. |

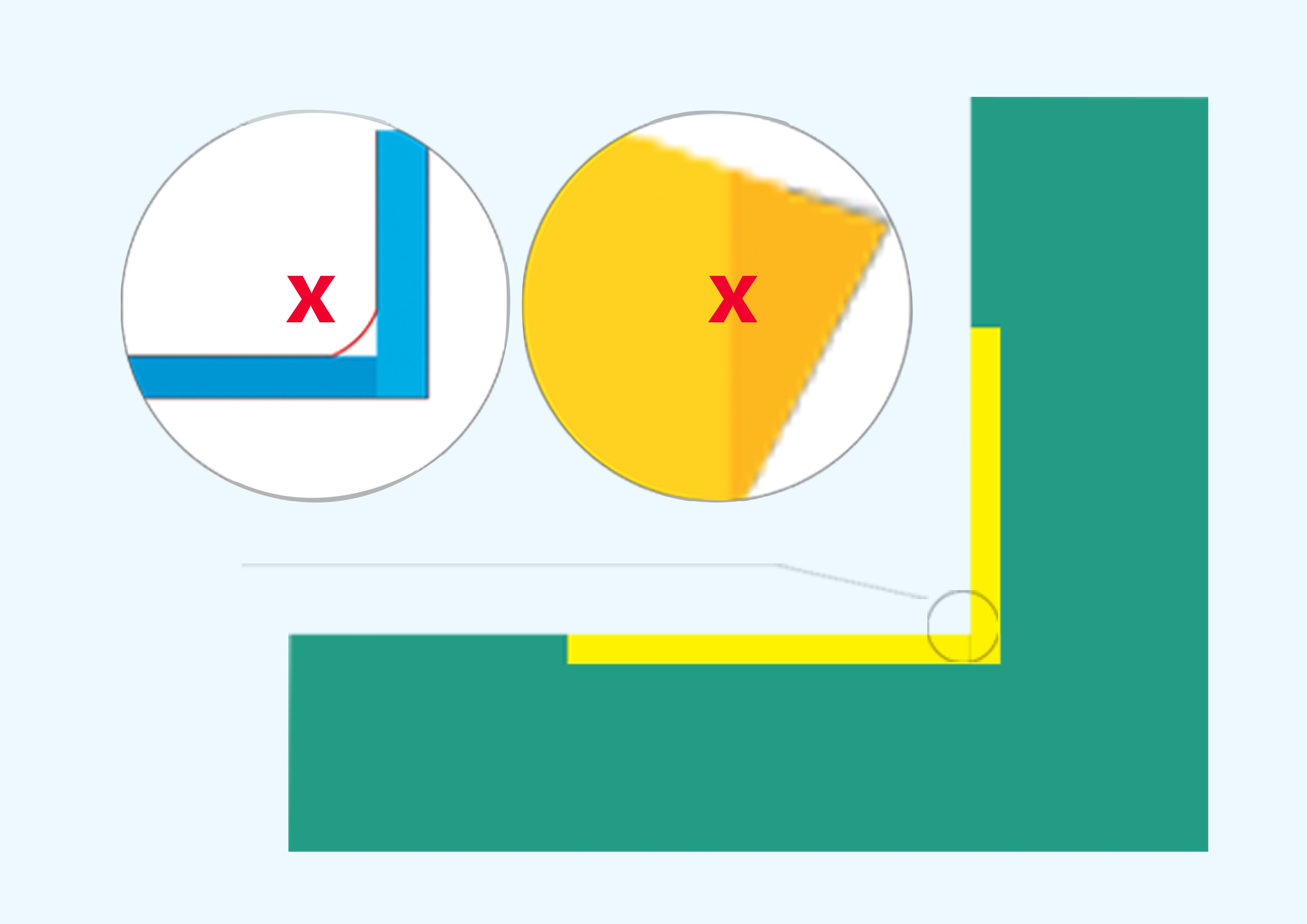

| Advanced AlgorithmObvious elimination of distorted, rounded or lifted corners. |

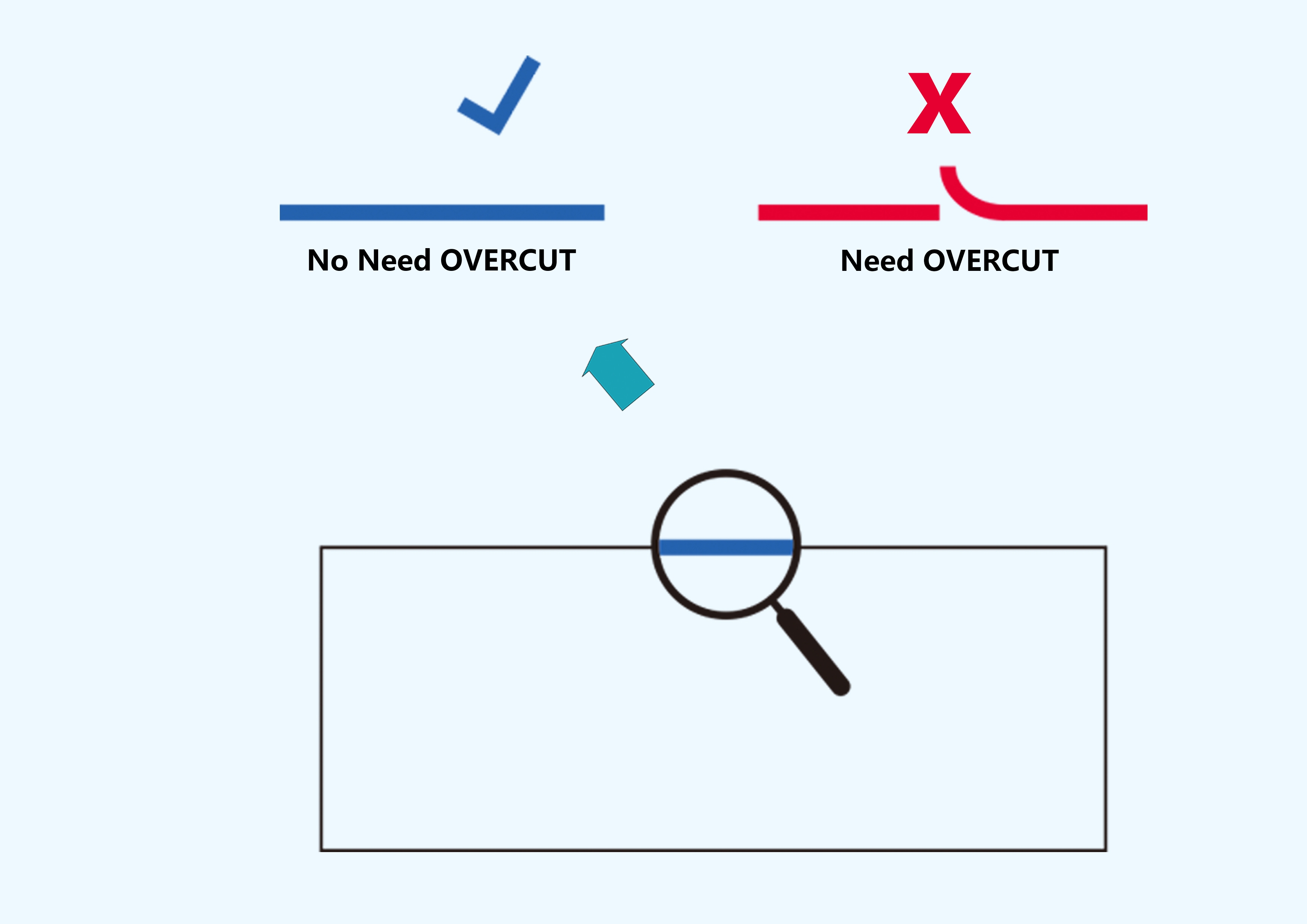

| No Need OVERCUTIn every cutting path, the start and end nodes join with each other accurately, while no need to setup any OVERCUT. |

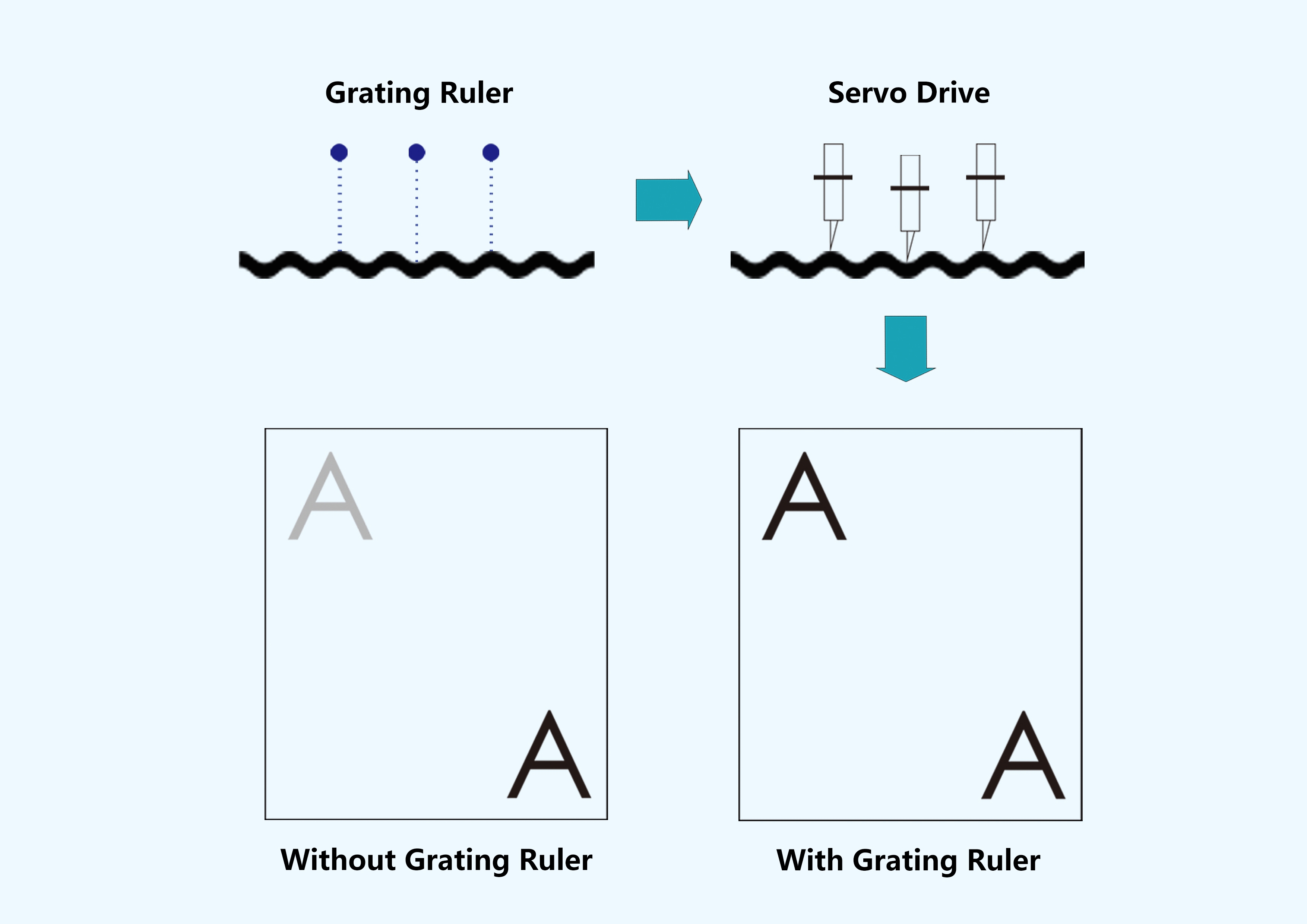

| Grating RulerInevitably the material surface is not at the same height from point to point, the Grating Ruler is applied to measure the distance between blade tip and material surface, and the cutting depth is adjusted in every 0.01mm by the controller accordingly. Then the blade travels up and down as material surface goes to keep the same cutting depth at any position of the tool path across the entire table.In short, the cutting depth is consistent and no different shades. |

| Clean Smooth Edge QualityThe Grating Ruler and correspondent cutting force management deliver clean smooth edge quality, even for the most complex jobs. It is easy to peal off the waste material, which cut down workload greatly for the users. |

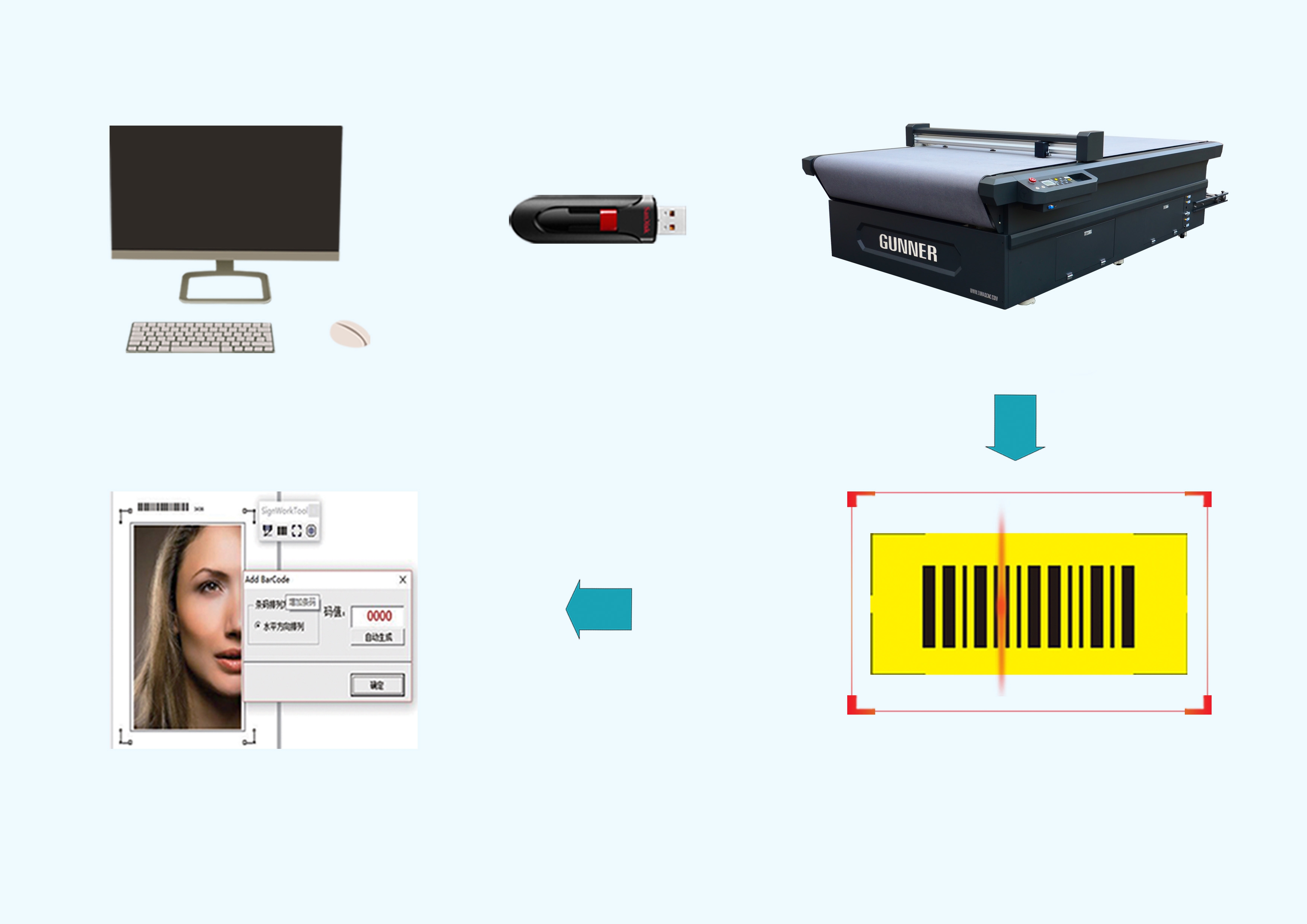

| Scanning Bar-code Offline with USB MemoryOne-click to recognize the cutting job from those saved in the USB memory by scanning the Bar-code which is pre-printed, while not requiring to connect to computer. This function is especially helpful to increase the productivity when there are many files stored in the USB memory. |

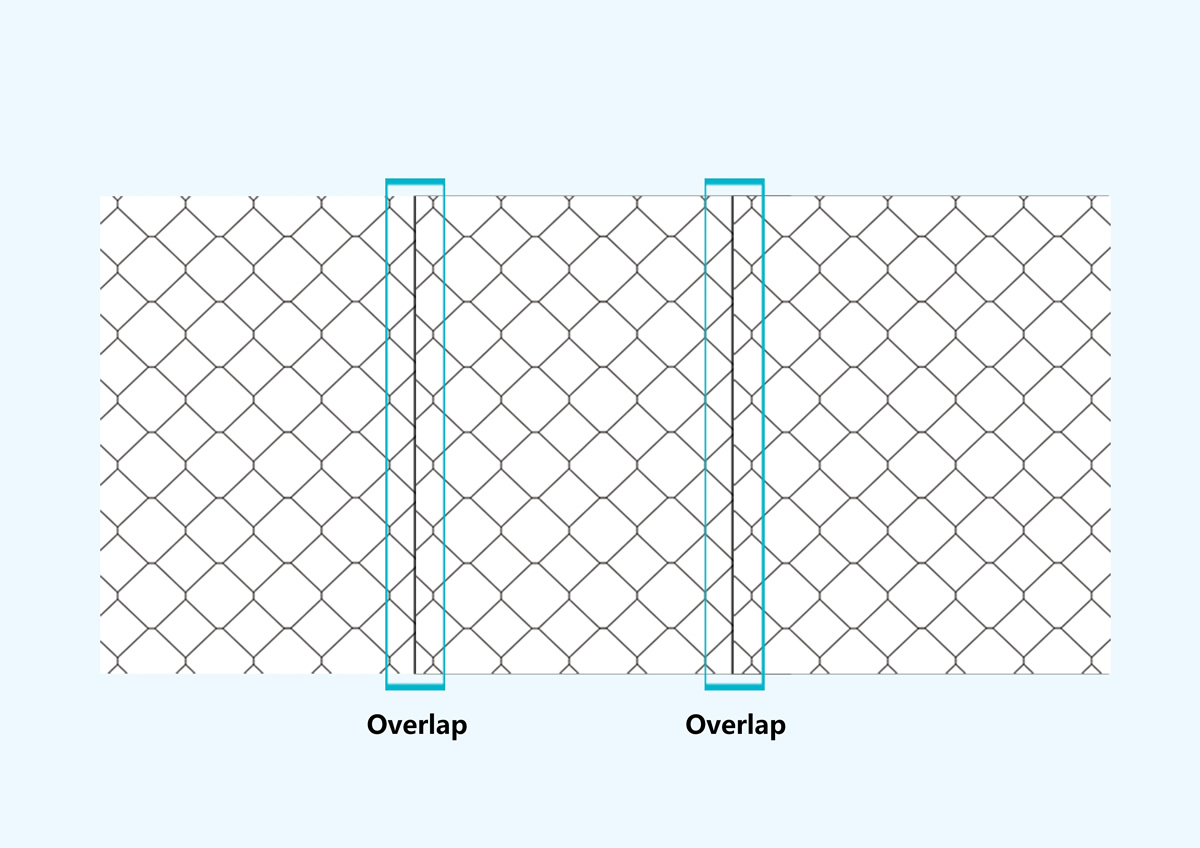

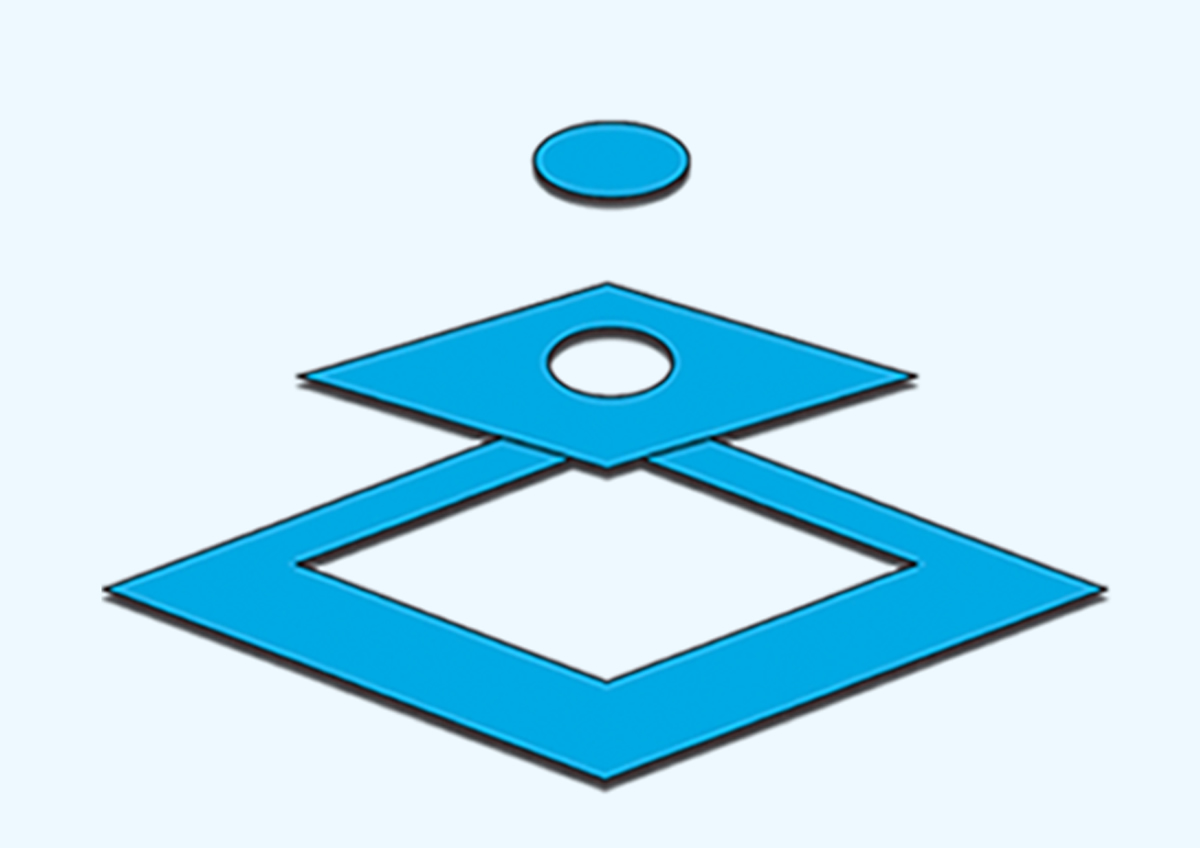

| Intelligent Bleeding for Easier Overlap OperationIntelligent Bleeding function makes overlap operation easier for the installers, this feature is very important for making and installation of big signs / indicators. |

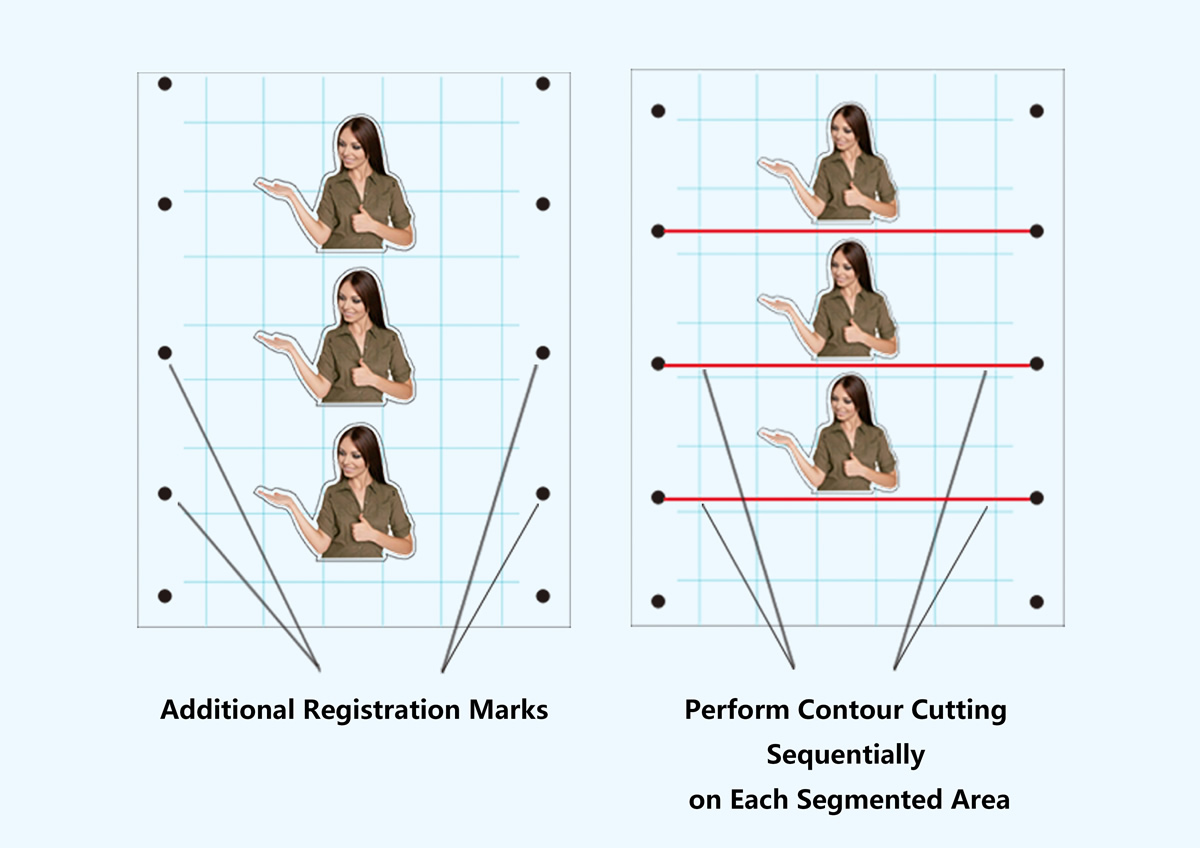

| Segmented Area Cutting OperationAdditional marks are available for more precise axis alignment. |

| USB Memory / Duplicate Cutting Jobs OfflineKnowing exactly what trouble the users and what they want, we design the cutter to fix those practical headaches. With our machine,users are enabled to duplicate the cutting jobs offline, which is much convenient than doing that with connecting to PC by USB cord. The function of duplicating cutting jobs with USB memory is a leading technology that developed by our-self. |

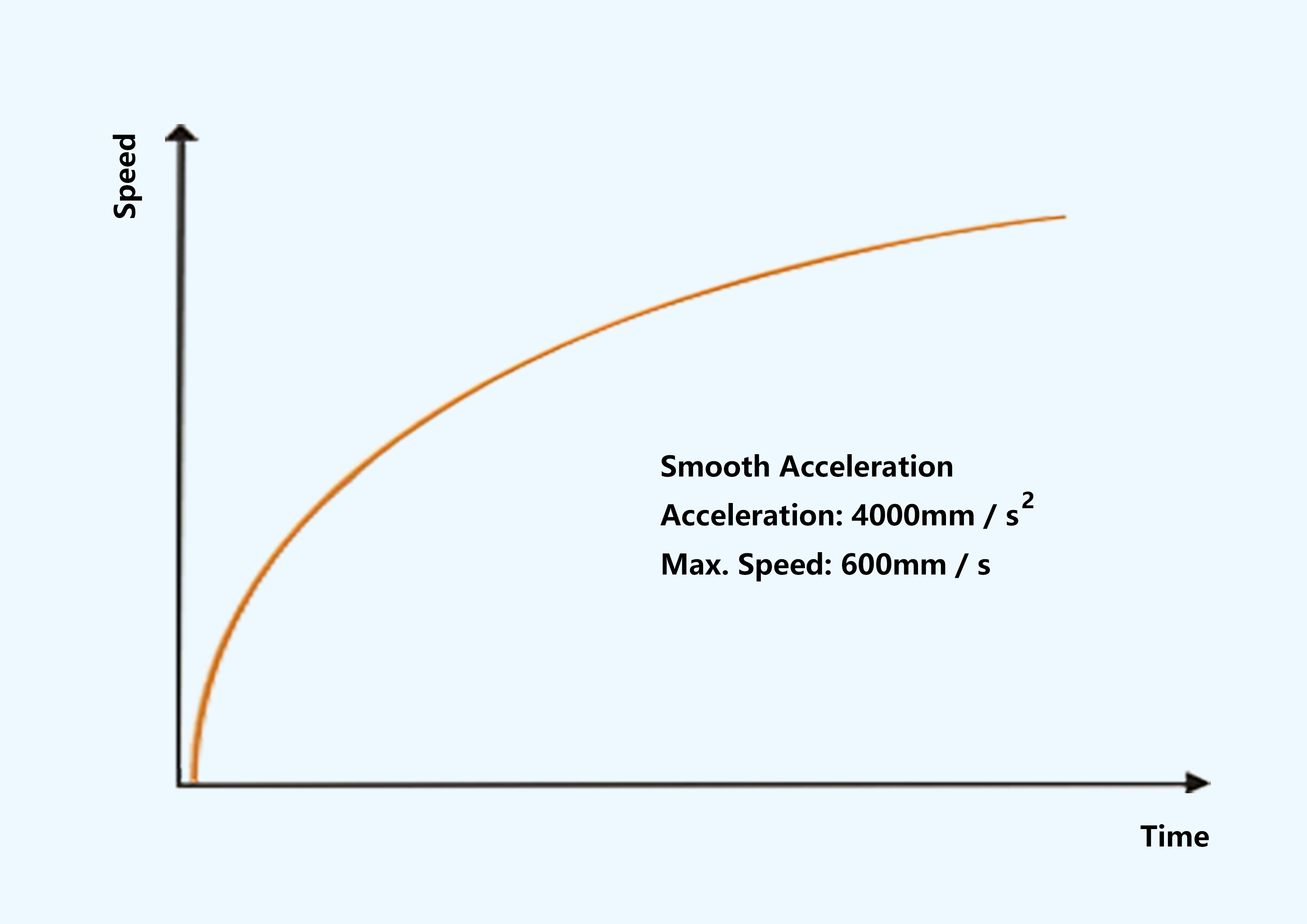

| Fast Cutting / Plotting OperationFast speed for volume production; Servos bring out smooth acceleration, big torque, precise cutting / plotting and excellent durability. |

| Advanced Tool CarriageThe tool carriage is in the structure of sports car, it’s driven by silent voice coil motor. The tool carriage is featured as fast, agile and no overheat for long-time non-stop operation. It is a leading tool carriage in the same field. |

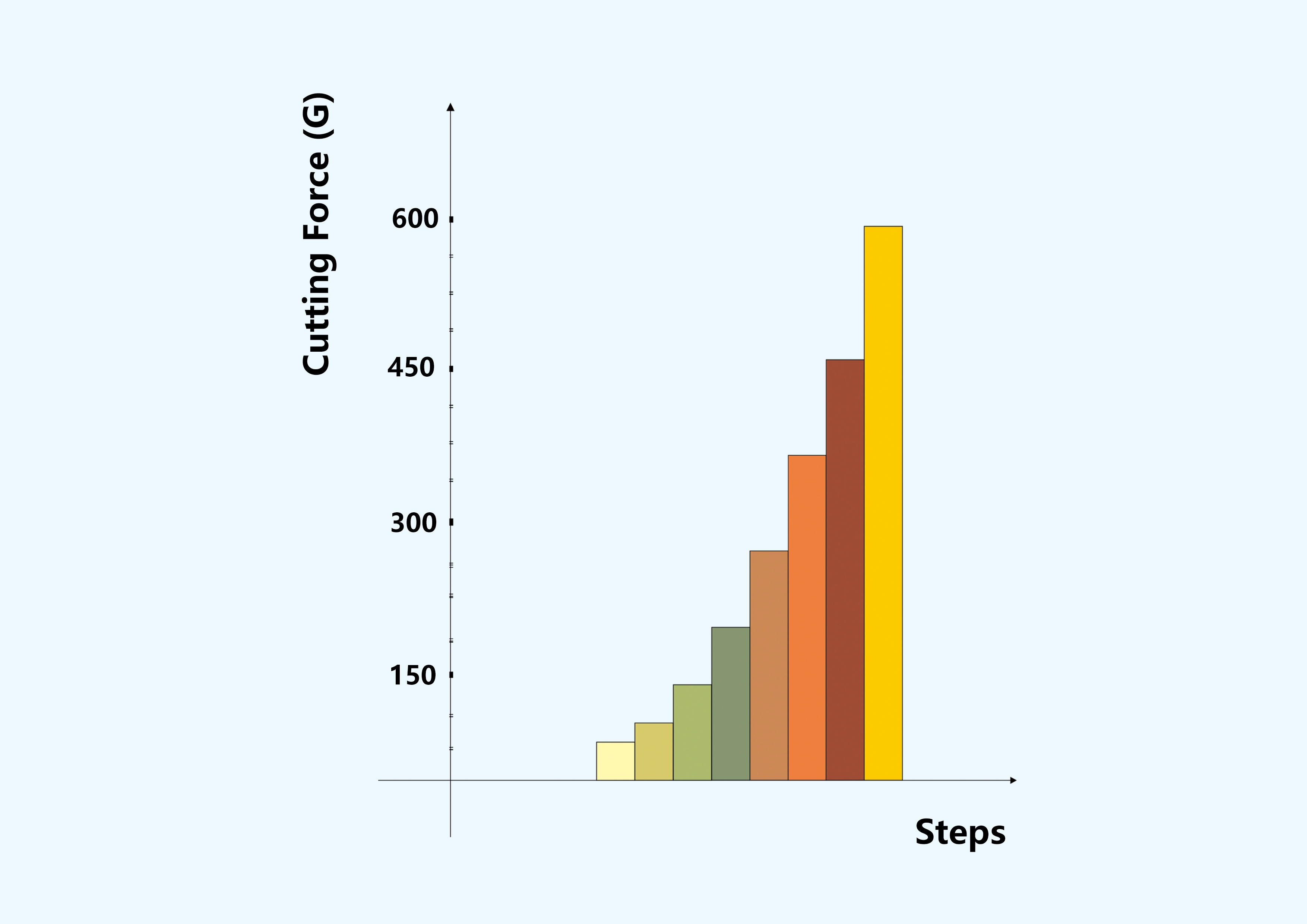

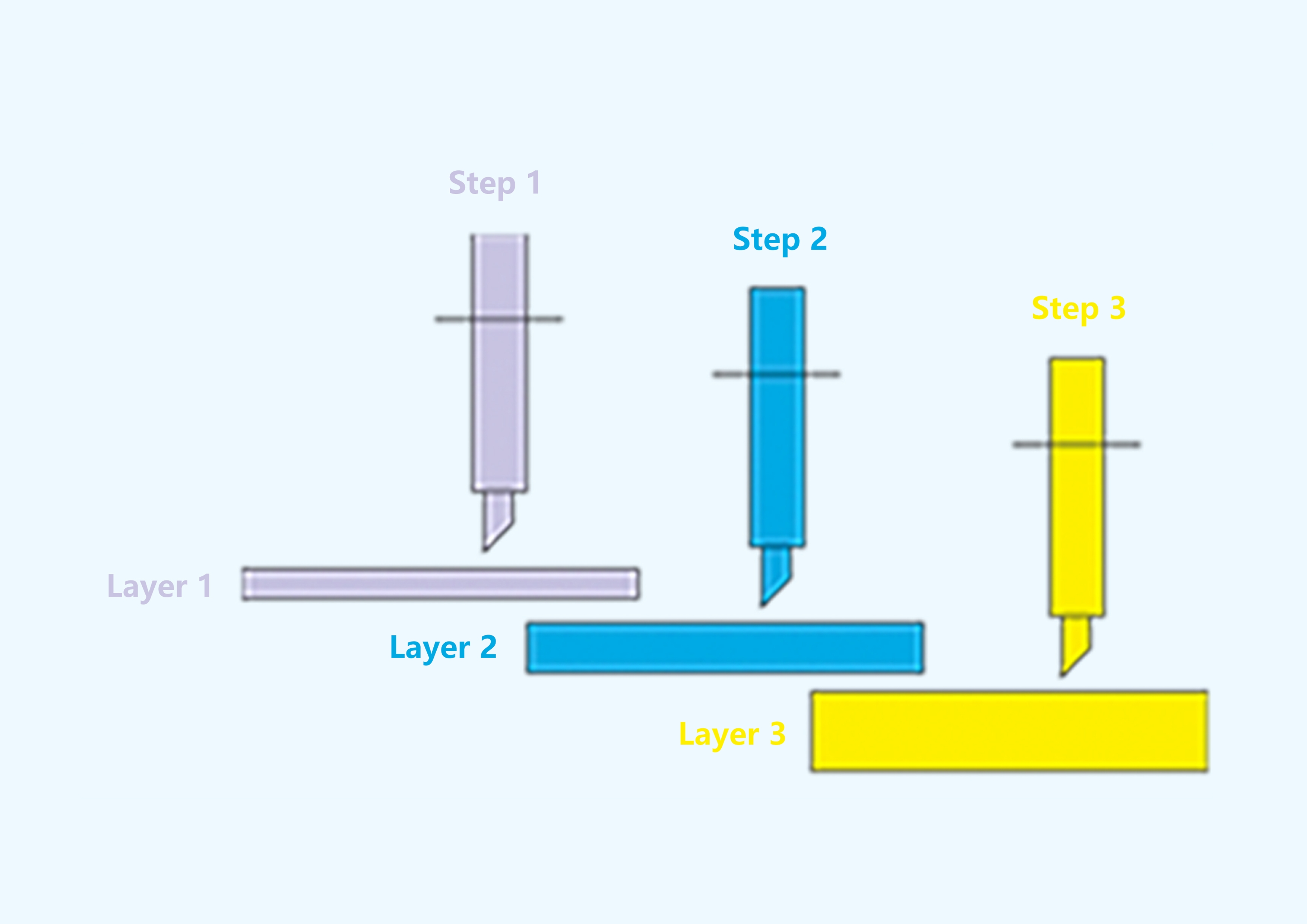

| Cutting Force in 8 StepIn Gunner’s software- CADtoPlotPro, user is enabled to put different colors for different cutting paths, and set the processing sequence as color sequence. |

| Multiple Layers SolutionFor medias with multiple layers, different cutting force is applied for different layer. |

| Half Cut / Perforation CutHalf cut / Perforation cut are available, every time you may carry out either one or both. |

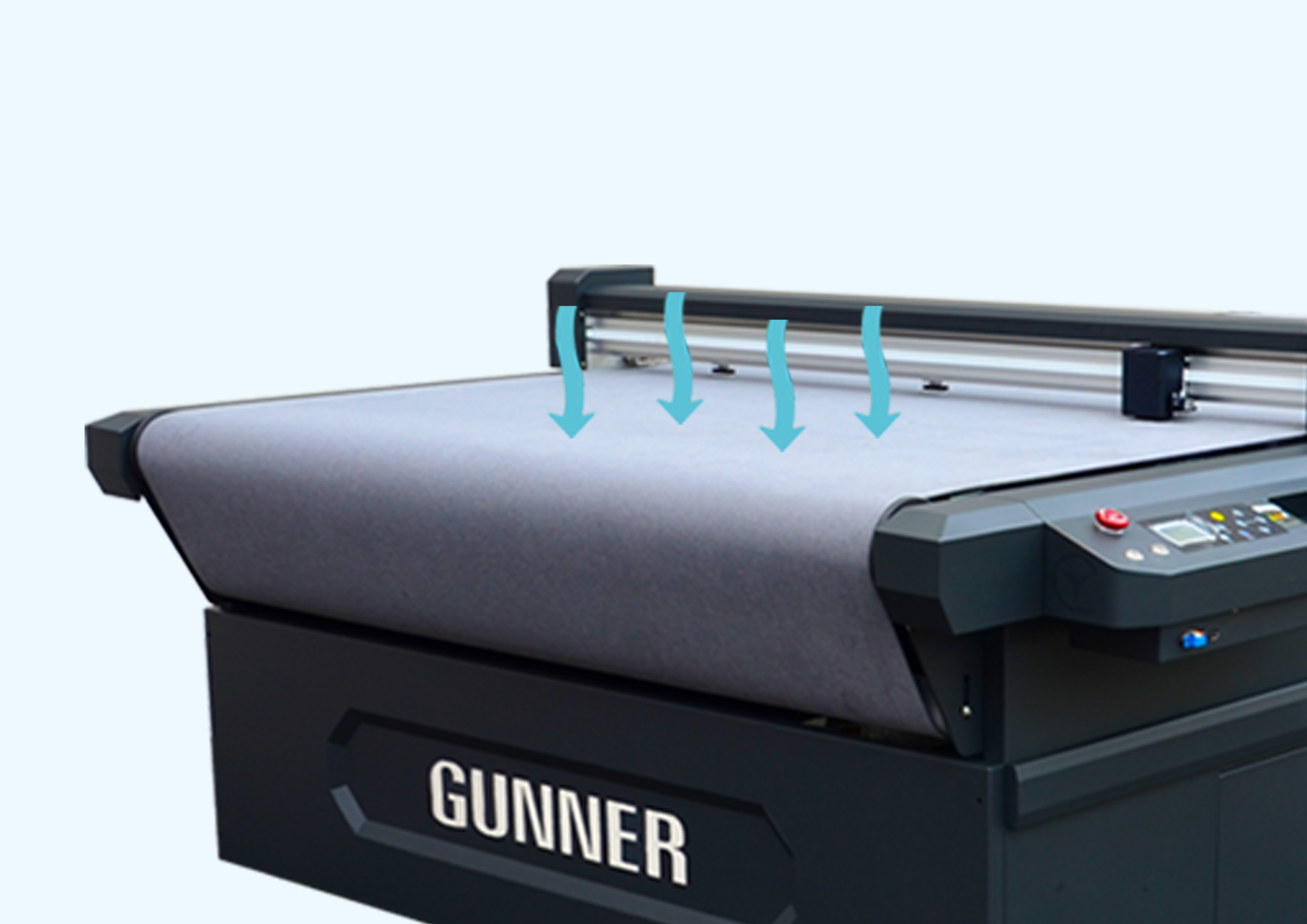

| Vacuum SystemStrong air flow to hold down the media flatly and tightly against the table top so that the tool carriage can perform fast, accurate cutting / plotting. |

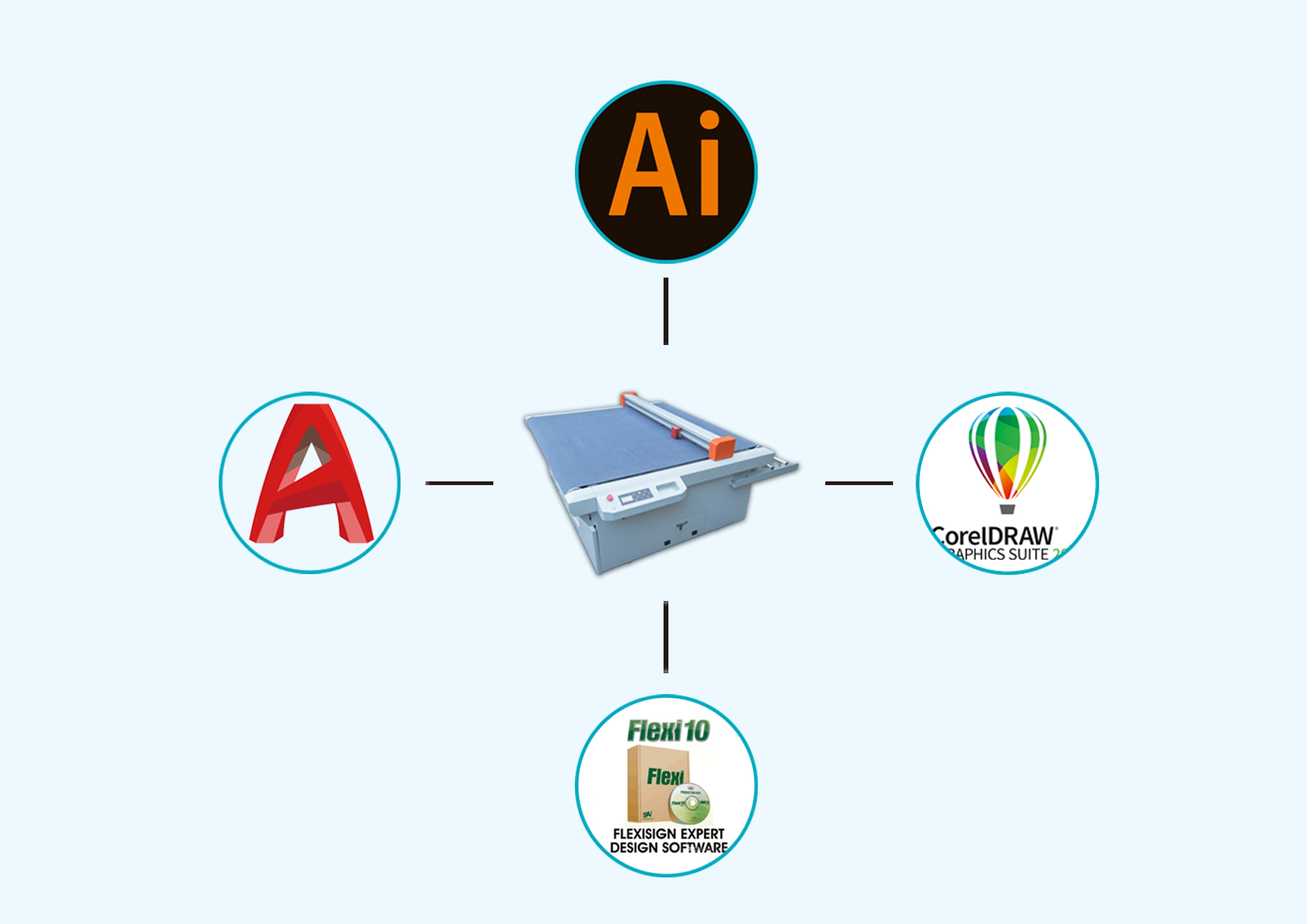

| Compatible with AutoCAD, AI, Coreldraw and FlexisignLeading the same industry, we make software by our-self, we are able to adapt our system to the latest version of popular CAD / CAM software, such as AutoCAD, Adobe Illustrator, Coreldraw and Flexisign. |

| Handshake ProtocolWe supply Software Development Kit / SDK to match with client’s software, which deepen cooperation between Gunner and Professional clients. |

| DXF Direct OutputGunner cutter is compatible with DXF file directly while no need any format transition. |

| One-click to Install Print DriverSend cutting jobs by any CAD that with printer feature. |

| Quality ComponentsFor outstanding performance and long-term reliable working, we only use world class brand name components like BANDO belt, NMB bearing. |

| NMB BearingWell known as high precision, stability and long working life. |

| Ultra-silence GuidesMade by WON Korea with ultra-silence, high load and high rigidity. |

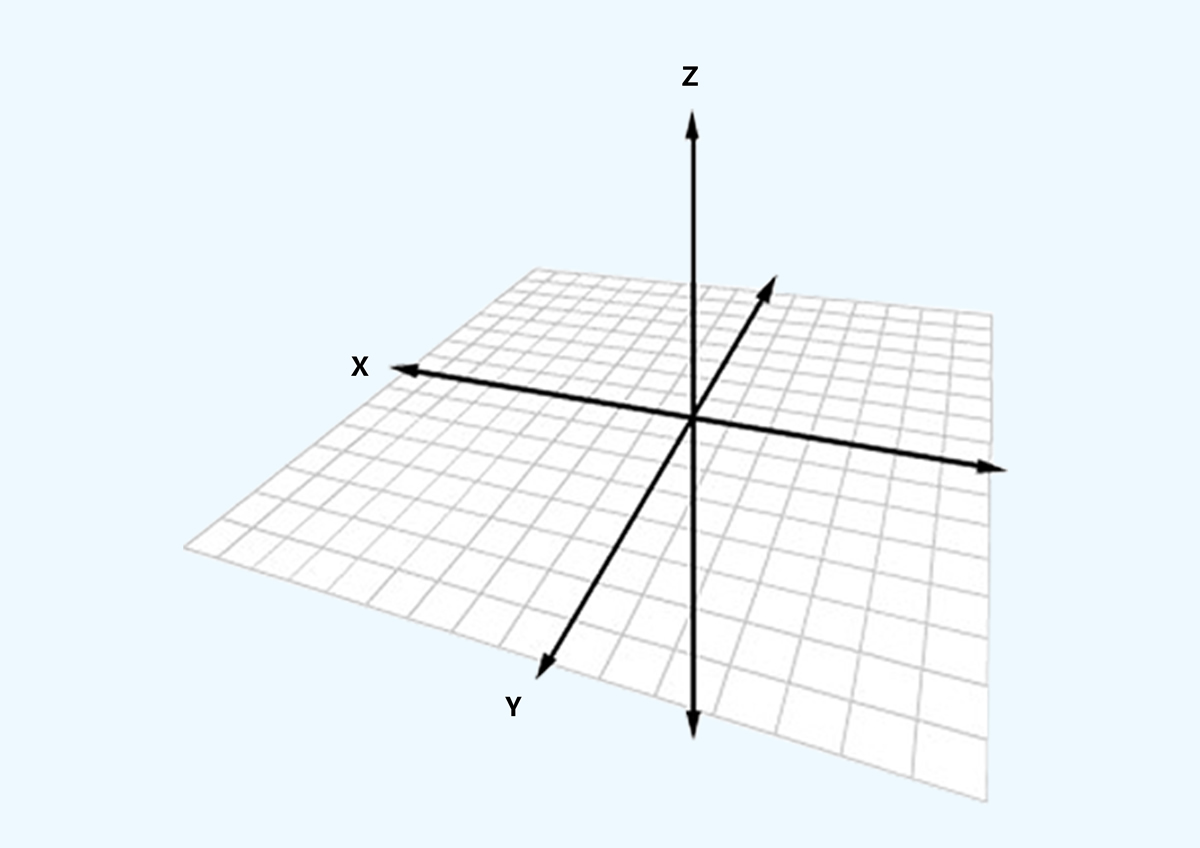

| Leading CalibrationIndustry leading technology is applied to calibrate the perpendicular between different axes and the parallelism between track of gantry and table top. |

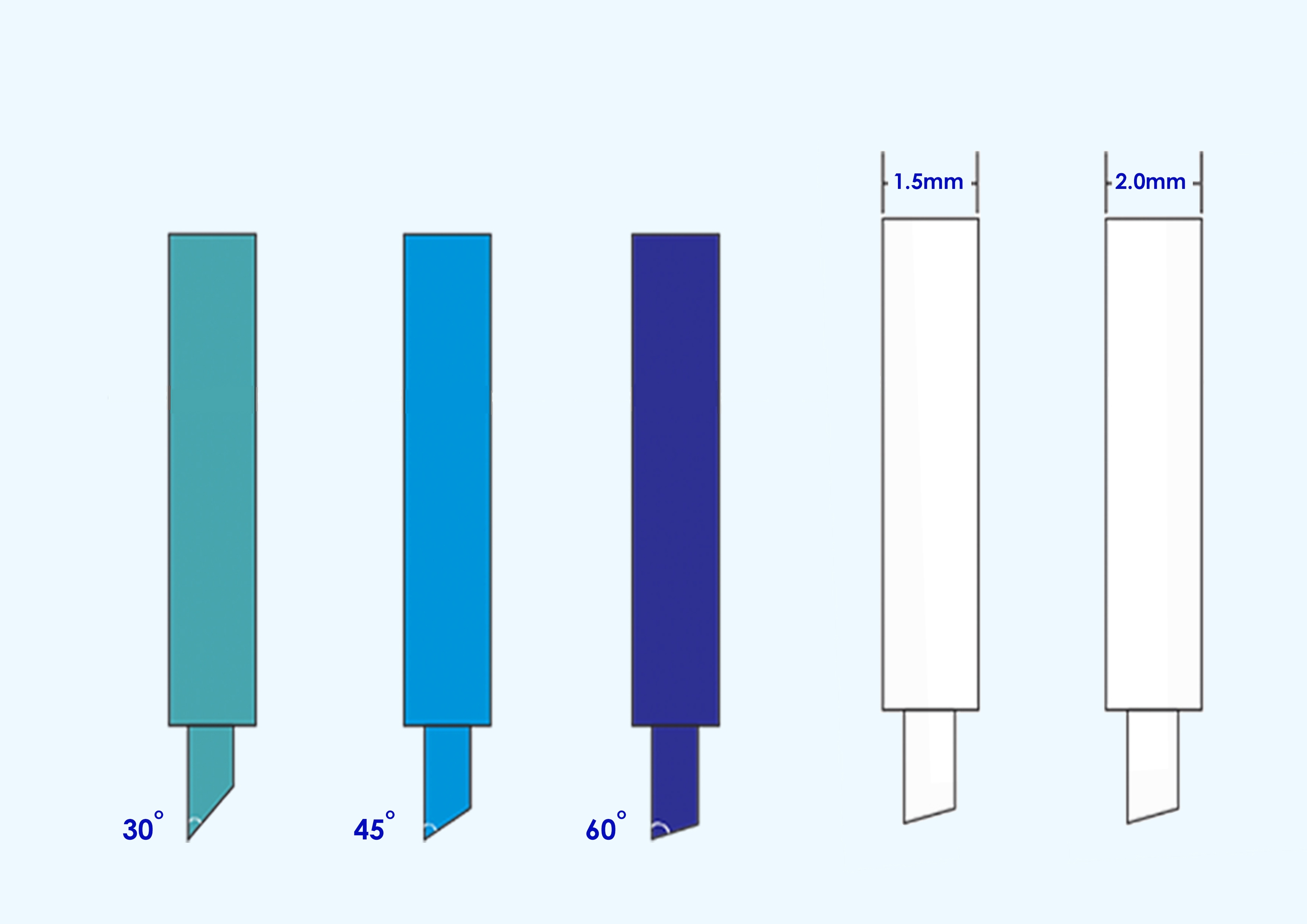

| Series Cutter Blades AvailableVarious Cutter Blades ApplicableAngle: 45° / Φ1.5mm for thick media |

Specification

| Model | GR1312F GR1325F |

| Working Size | 1300x1200mm(non-contour) 1300x2500mm(non-contour) 1240x1180mm(contour cutting) 1240x2480mm(contour cutting) |

| Applicable Media Thickness | ≤1.5mm |

| Applicable Media | Reflective Sheeting |

| Method to Feed Media | Conveyor & Roll Media Bracket |

| Method to Fix Media | Vacuum Table |

| Max. Cutting Speed | 600mm / s |

| Max. Cutting Force | 600G / 5.8N in 8 Steps |

| Cutting Force Setup | Adjustable in every 1G |

| Cutter Blade Diameters | Φ1.5mm , Φ2.0mm |

| Cutter Blade Angles | 30° , 45° , 60° |

| Dotted Lines Cutting | Included |

| Drive | AC Servo |

| Mechanical Resolution | 0.0125mm |

| IOS | Win10 / 8 / 7 / XP |

| Memory Buffer | 2MB |

| CAD/CAM Software | Windows Driver , SignWorkPro , CADtoPlotpro |

| LCD | English/Chinese |

| File Format | HP-GL , PLT |

| Port in Standard | USB , RS-232 |

| Registration Marks Recognition | CCD camera |

| Power Input | 220V AC , 50-60Hz |

| Power Consumption | 2.6KW 3.0KW |

| Cutter Holder | 1 |

| Roll Media Bracket | Included |

| Package Size L-W-H | 1920x1850x1220mm 3120x2150x1220mm |

| Gross / Net Weight | 320/240KG 850/620KG |

Download